I hadn’t seen a presentation by Rob since I saw him a couple of years ago at a local woodshow when he was working with Lie Nielsen. He was a familiar face at these shows and I always looked forward to seeing him there each year. I also missed him back in 2007 when he spent the day with the Atlantic Woodworkers Association. It was great to be able to catch him here at Busy Bee.

Rob earned a Bachelor of Science in Industrial Technology / Furniture Design at Brigham Young University where he was Dr. Dale L. Nish’s teaching assistant. (Woodturners reading this may find that little tidbit rather interesting, I certainly did! 😉 ) Rob has worked some of the world’s master craftsmen, including Alan Peters, Sam Maloof, Tage Frid, Monroe Robinson and Peter Korn. He has operated a custom woodshop in New Brunswick since 1989 and up until a few years ago worked as a sales rep with Lie Nielsen. Now, in addition to offering workshops, seminars and training, he develops and promotes a full line of instructional videos and tools

Rob began his presentation with an explanation and demonstration of his time-honored sharpening method. He honed a plane blade on a 1000 grit stone first and then he created a microbevel on a 30000 (that’s 30K!) stone. This was followed by creating a smaller, finer bevel (a micro-micro bevel?) that he did using a small steel ruler as a jig, which he refered to as the ‘Charlesworth ruler trick’, a technique he learned from furniture maker, David Charlesworth.

Although the actual sharpening process takes only a couple of minutes Rob took the time to clearly explain every step, some tips and tricks and why he was doing something and why he wasn’t doing something. Because sharpening hand tools is often viewed as a mystery there were many questions regarding this which Rob happily answered, ensuring that it was understood before continuing on with his presentation.

Once the blade was sharpened it was fitted into his plane and he showed us how to first set up the blade, how to start planing and then how to plane. And boy, did he plane! The shavings were streaming out of the plane like ribbons. They were so thin, gossamer thin in fact, that they would float and flutter in the air! Here you can see the tissue-like shavings produced by this finely sharpened blade:

Rob allowed several of us to try our hand at using the plane, to see what this sharp blade felt like. Let me tell you, it felt great! We were planing hard Maple and there was very little effort required to create a smooth, finished surface. Here, you can see my friend and fellow AWA member, Phil, using just one hand to produce a beautifully thin shaving:

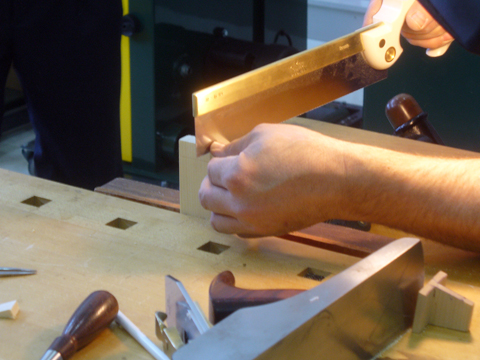

From here, Rob segued into his ‘4 Minute Dovetails’ by simply asking, “So, who wants to see a 4 minute dovetail?” Of course, we all did! 🙂

The “4 Minute Dovetails” came about after Rob saw a video of Frank Klausz cut a set of dovetails, pins first, in three minutes using a special bowsaw blade. Rob decided to show that it can be done by cutting the tails first.

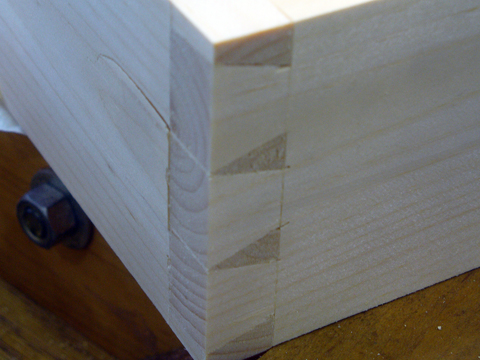

Here’s a closeup:

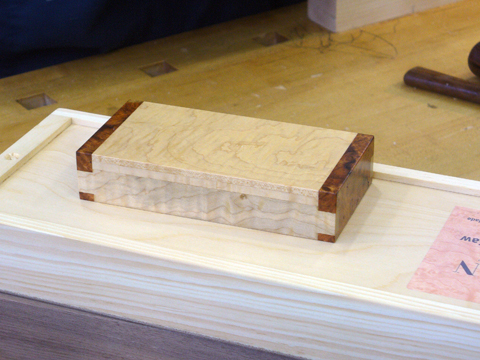

And here is the final product. Not bad… not bad at all… 🙂

Here’s a video so that you can see it for yourself:

Wow! Three minutes and forty seconds! And all while explaining it to us too!

(To be fair 🙂 , the video of Frank Klausz cutting his dovetails is here)

You may have noticed the saw that Rob was using in the photos above. This is a new tool that he has developed and that will be on the market soon. Rob gave us a short history of dovetail saws, telling us the problems that he found in most that are on the market today and the changes that he incorporated in his saws to overcome them. Some of the features of his saws include an easy-start tip, stronger backs, balanced heft and a Swanstone handle.

We were given a chance to try these saws and we all agreed, they are beautiful saws! The easy-start tip is a blessing and the weight makes the cut effortless. Kudos!

Rob also sells a line of hand-crafted boxes. Unfortunately, photos don’t do them justice, since beholding in in the holding. Here are a couple of them:

Here is a box that students in one of Rob’s workshops get to make:

Rob finished the session with sharpening chisels and plane blades that a few audience members brought in, again fully explaining the honing process.

More instructional than a sales pitch, Rob’s presentation style is laid-back, friendly and honest. There is no hard selling here. Rob understands fully the issues that we, as woodworkers, have with planing, sharpening and dovetailing. He also knows that we desire to know more, to be able to do as he does. Patiently and methodically he takes the time to tell us how to do it and then he shows us how to do it, and like today, allows us to try it. Rob looks you straight in the eye when he’s speaking to you. As in his videos, this presentation was like having a good friend at your shop giving you a hand. A coach, indeed!

Thanks, Rob, for a great afternoon!

For more information about Rob Cosman and his full line of products drop by his website located here.

Update – January 6th, 2010: Rob just sent me his latest world-breaking video. This time he does a six and a half minute BLIND dovetail! Don’t believe me? Here, have a look:

Back to the shop…