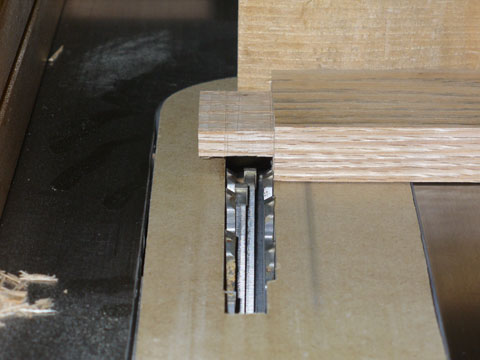

I made the tenons on the tablesaw using the dado blade. I had looked at tenoning jigs, the bandsaw, etc. but this seemed to be the quickest and easiest way. It was just a matter of repeated passes over the blade to remove the unwanted wood:

I used a stop block next to the fence and positioned it to allow the maximum tenon width. Using the stop block ensured that the tenon would not jam against the fence as it was being cut. Once the wood got past the stop block there was nothing for it to jam against:

Because the plunge router creates rounded end mortises you have the choice of either chiseling the mortise square or rounding the tenon ends. I chose to round the tenon. I did this with a carving knife and simply cut and shaped to fit:

Here is the frame put together. You can see that even without glue the mortise and tenons fit snug enough for the frame to stand on its own. You can also see that there is still sanding required to remove the old finish:

And here is the project with the table top laid on the frame, giving a view of the progress so far:

Next I have to mortise the top skirts and the bottom stretchers on the short sides for the upright end slats, as well as cut and tenon the upright end slats. I also have to mortise the bottom stretcher for the bottom shelf and then cut and tenon the bottom shelf.

You can follow along with the building of the rest of this project via these links:

Back to the shop…