However, I was able to get out there for a few hours and turn a small bowl out of Walnut. The bowl is 5″ in diameter and 1 3/4″ tall with straight sides and a shallow curved bottom:

I found the walnut fairly easy to turn, in fact, quite enjoyable. It finished up well too. Walnut always finishes with a look of elegance, as confirmed by even my limited turning skills. 🙂

Here’s a sequence of photos showing the steps I took to create this bowl.

This first photo shows how I cut the bowl blank out of a chunk of walnut using the Circle Cutting Jig

This is the completed bowl blank:

Next, the bowl blank is mounted on a faceplate:

And then mounted on the lathe with the bottom of the bowl facing you:

This photo shows the bowl with the side and bottom curve completed. At this point the finish is also applied. In this case, I’m using a beeswax and linseed oil mixture called Tried And True The photo also shows the tenon which will be used to mount in the chuck:

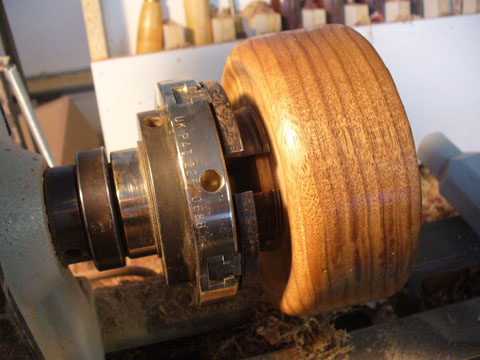

Here is the bowl now reversed with the tenon mounted in the chuck:

Here is the bowl with the inside being cleaned out:

Here is another shot of the inside of the bowl almost completed:

And here is the inside completed. Again, the finish is applied.:

Next, the bowl is reversed again and mounted on the chuck with ‘jumbo jaws’ installed. The ‘jumbo jaws’ have rubber wheels that hug the bowl, therefore it does not making marks. Using the ‘jumbo jaws’ will allow you to remove the tenon.:

Here is the finished bottom. I didn’t remove the tenon completely. Instead, I rounded it off, turning it a bit lower that the outside foot, giving the bottom a different look:

And there you have it, a small walnut bowl:

I believe one of the biggest reasons why woodturning is so popular among woodworkers is the fact that in only a few hours a project can be completed, giving a great feeling of accomplishment and success.

Back to the shop…